What is Backflow and Why is it a Danger?

A backflow prevention device is a crucial plumbing component that protects your drinking water by preventing contaminated or non-potable water from flowing backward into your clean, potable water supply.

- Purpose:

- Protects potable (drinkable) water from contamination.

- Acts as a one-way valve, ensuring water flows only in the intended direction.

- Safeguards public health by preventing harmful substances from entering the water system.

Normally, water flows into your home from the municipal supply. However, changes in water pressure can cause a reversal called backflow. This can pull unsafe water, chemicals, or other contaminants into your clean drinking water lines.

This is critical for potable water safety. When backflow happens, it creates a “cross-connection,” a direct link between clean and contaminated water sources. This contamination can introduce harmful substances into your water, creating a serious public health hazard. It’s different from pollution, which might affect taste or smell but is not typically harmful.

History shows the severity of this issue. A devastating backflow disaster at the 1933 Chicago World’s Fair occurred when poor plumbing allowed sewage to contaminate drinking water. This caused a widespread amoebic dysentery outbreak, leading to around 100 deaths and over 1,000 illnesses, highlighting the urgent need for robust backflow prevention.

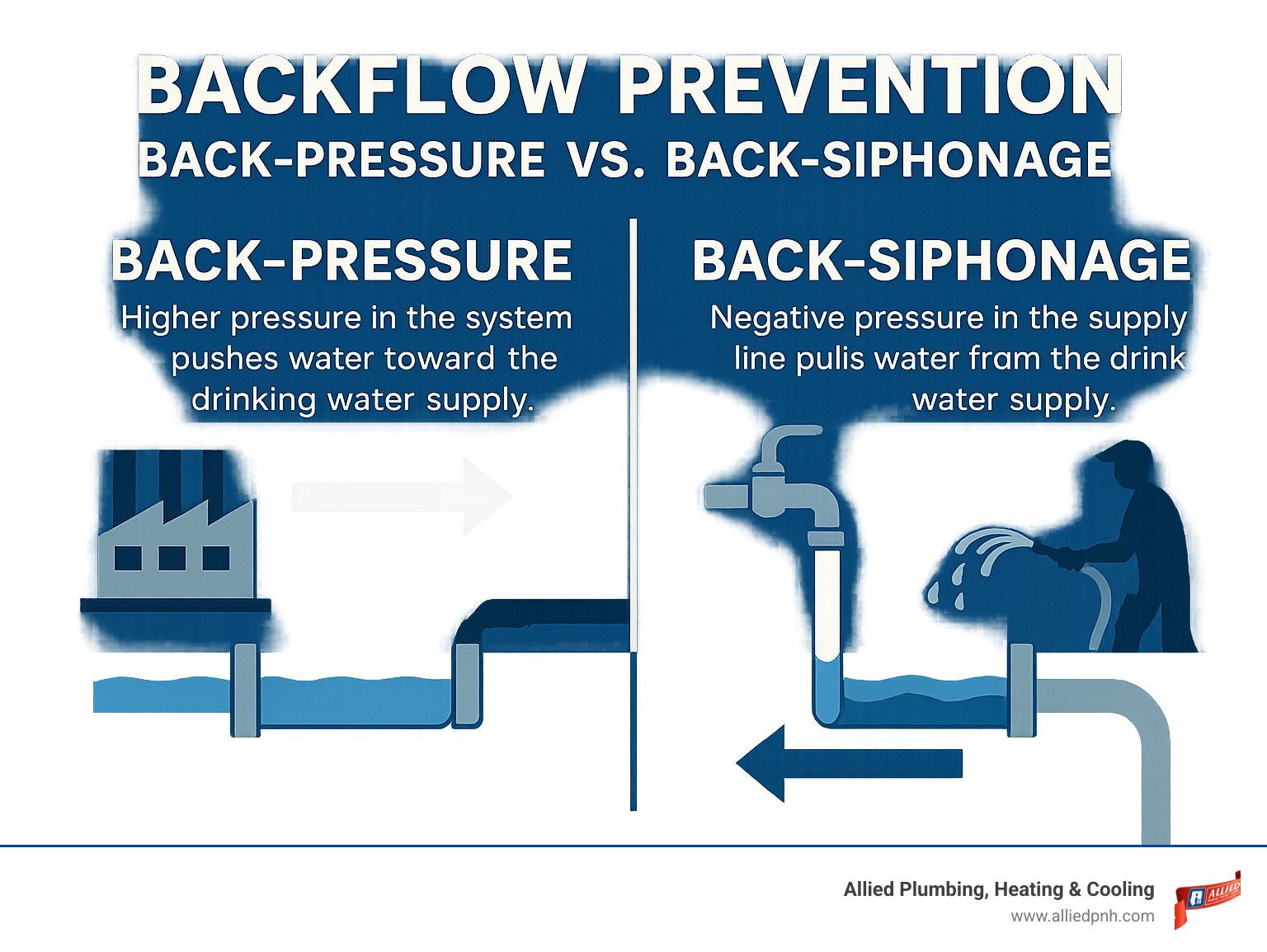

The Two Causes of Backflow: Back-Pressure and Back-Siphonage

Backflow, or water flowing the wrong way, happens for two main reasons: back-pressure and back-siphonage. Understanding these two causes is key to protecting our drinking water. Simply put, one pushes contaminated water, and the other pulls it into the clean supply.

Back-Pressure Explained

Back-pressure occurs when your property’s internal water pressure exceeds the municipal supply’s pressure. This imbalance can force water from your system back into the public water lines, potentially carrying contaminants with it.

Several situations can create this pressure imbalance:

- Booster Pumps: Used in large buildings, these can create internal pressure higher than the city supply, causing back-pressure.

- Liftd Tanks: Water stored in tanks at a higher elevation can create hydrostatic pressure that pushes water backward.

- Thermal Expansion: In a closed system, water heating and expanding can build up enough pressure to overcome the city’s supply pressure.

- Interconnected Systems: A property connected to an auxiliary water source (like a well) operating at a higher pressure can cause back-pressure into the potable water lines.

Back-Siphonage Explained

Back-siphonage occurs when a sudden, significant drop in the main water supply pressure creates a vacuum. This negative pressure can suck non-potable water from a cross-connection into your clean water system, much like sipping a drink through a straw.

What can cause such a sudden drop in city water pressure?

- Water Main Breaks: A burst main causes a rapid pressure drop in surrounding lines.

- Firefighting Demand: Fire trucks drawing large volumes of water from hydrants can drastically reduce pressure in the nearby system.

- Excessive Water Usage: Any unusually high demand on the water system can temporarily lower pressure enough to create conditions for back-siphonage.

Understanding these pressure dynamics is crucial for water safety. If you’ve experienced pressure issues, our guides on Solving Low Water Pressure Issues from Plumbing and Identify and Fix Water Pressure Problems can help. This knowledge helps us protect your home with the right backflow prevention device.

What is a Backflow Prevention Device and How Does It Work?

A backflow prevention device is a mechanical safeguard, like a one-way valve, that ensures water only flows from the municipal supply into your property, never the other way. Its main job is premise isolation: creating a barrier between your property’s plumbing and the public water supply.

These devices use a pressure differential or a physical air break to make it impossible for contaminated water to enter the potable supply. Plumbing codes require protection at every cross-connection, with the type of device depending on the hazard level.

Low hazard situations involve pollutants that affect water’s taste or appearance. High hazard situations involve contaminants like sewage or chemicals that can cause serious illness.

| Device Type | Hazard Level | Typical Application | Testability |

|---|---|---|---|

| Air Gap | High | Sinks, tanks, industrial processes (physical separation) | Visual |

| Atmospheric Vacuum Breaker (AVB) | Low | Hose bibs, residential sprinklers, laundry tubs | Non-testable |

| Pressure Vacuum Breaker (PVB) | Low | Irrigation systems, continuous pressure applications | Testable |

| Double Check Valve Assembly (DCVA) | Low | Fire sprinkler systems (non-chemical), commercial buildings | Testable |

| Reduced Pressure Zone Assembly (RPZ) | High | Industrial plants, hospitals, chemical systems, fire systems (chemical) | Testable |

The Main Types of Backflow Prevention Device

Let’s review the different types of backflow prevention device.

Air Gap

The air gap is the simplest and most effective form of backflow prevention. It’s not a mechanical device but a physical separation—an open vertical space between the water outlet and the potential level of contaminated water (like the gap between your faucet and sink rim).

This physical break makes backflow impossible. Because there are no moving parts to fail, it offers the highest level of protection, though it isn’t always practical for pressurized systems.

Vacuum Breakers (AVB & PVB)

Vacuum breakers are designed specifically to prevent back-siphonage.

The Atmospheric Vacuum Breaker (AVB) prevents back-siphonage by opening to let air in when water pressure drops, breaking the vacuum. Commonly found on hose bibs, lawn sprinklers, and laundry tubs, AVBs must be installed at least six inches above the highest downstream point and cannot be under continuous pressure.

The Pressure Vacuum Breaker (PVB) is a more advanced, testable version for continuous pressure irrigation systems. It uses a spring-loaded check valve and an air-inlet valve to stop back-siphonage. Unlike an AVB, it can handle constant pressure but must be installed at least 12 inches above the highest downstream point.

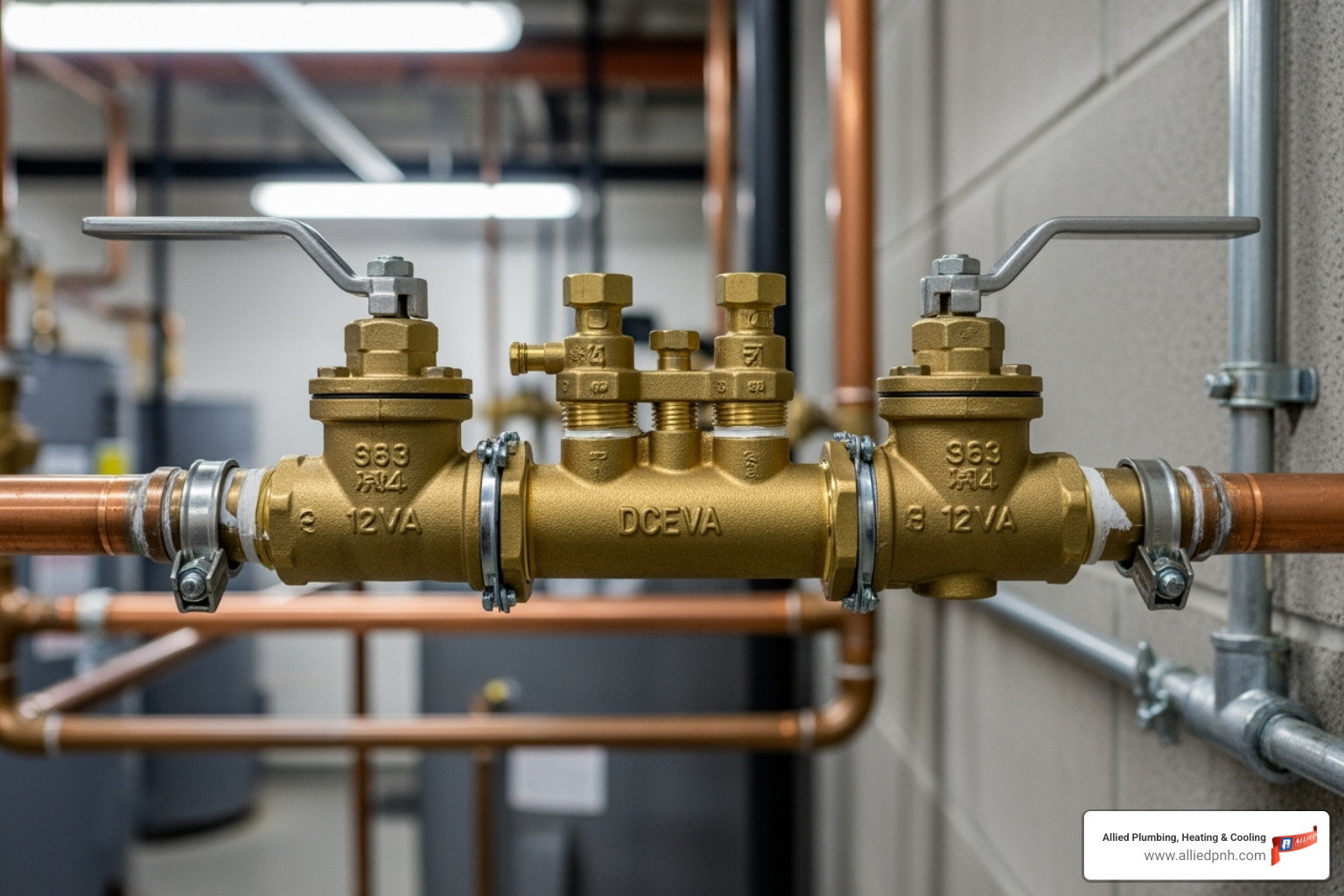

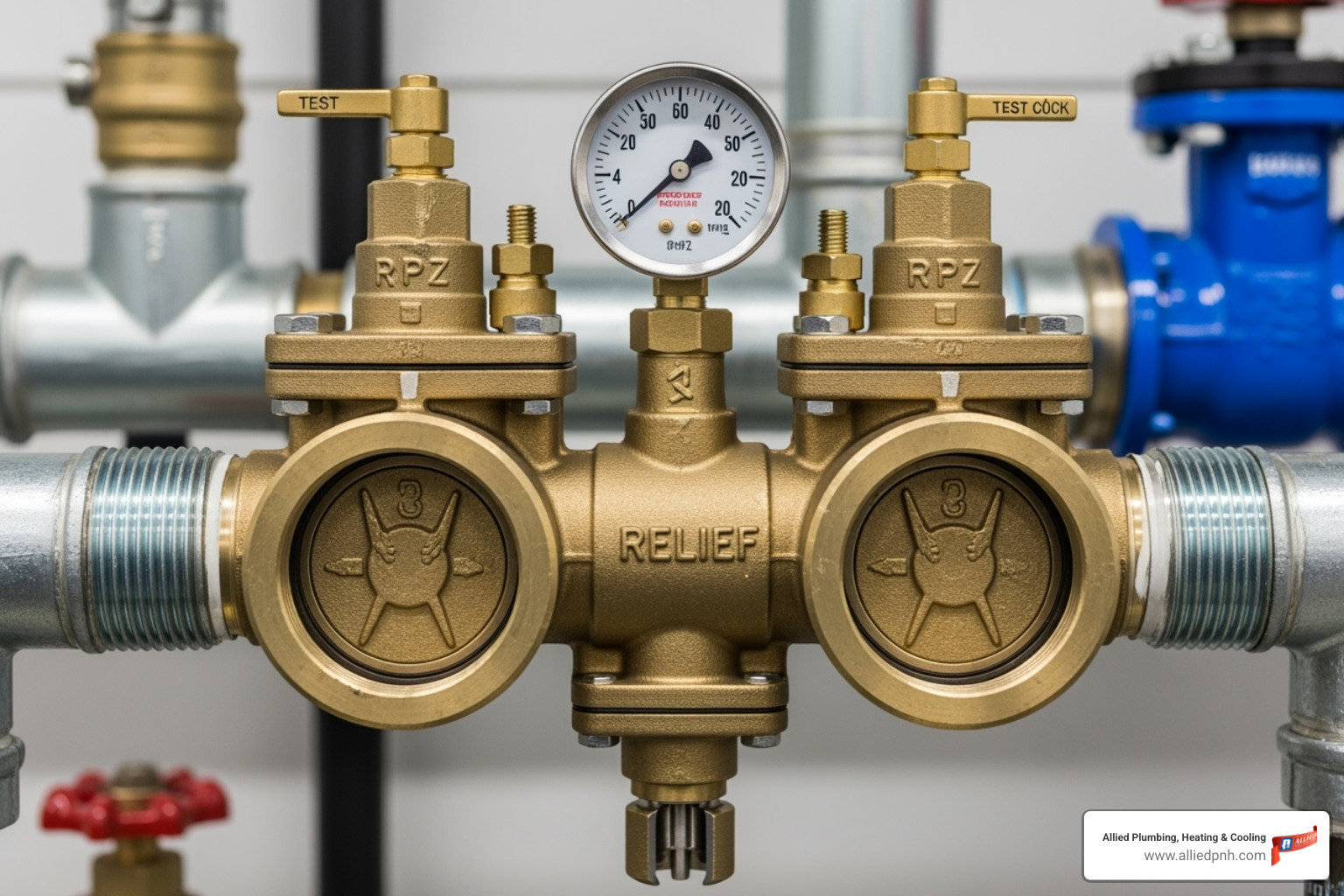

Check Valve Assemblies (DCVA & RPZ)

These are heavy-duty assemblies designed for both back-siphonage and back-pressure.

The Double Check Valve Assembly (DCVA) uses two independent check valves in series for redundancy. If one fails, the other prevents backflow. It’s used for low-hazard applications like non-chemical fire sprinkler systems and commercial buildings. Test ports allow for regular inspection.

The Reduced Pressure Zone Assembly (RPZ) offers the highest level of mechanical protection for high-hazard applications. It has two check valves plus a special differential relief valve in between. If backflow is detected, this relief valve opens and discharges water, providing a visible sign of a problem and preventing contamination.

RPZs are required in high-risk locations like industrial plants, hospitals, and systems with chemical additives. Organizations like The American Backflow Prevention Association help establish best practices and training for these critical devices.

Installation, Testing, and Regulatory Requirements

Installing a backflow prevention device is often a legal requirement. Regulations from bodies like the U.S. Environmental Protection Agency and local plumbing codes exist to protect public drinking water. These codes specify the type and location of devices needed, especially for commercial, industrial, or multi-unit residential properties.

In Illinois, the EPA provides detailed requirements for cross-connection control, which you can review at Cross Connection Control – Illinois EPA.

A key rule is the annual testing requirement. Testable devices like DCVAs and RPZs must be professionally tested upon installation, after any repairs, and annually thereafter. This ensures the mechanical parts are working correctly.

Installation itself follows strict protocols regarding accessibility, orientation, and height to ensure proper function and serviceability.

Who Can Install and Test a Backflow Prevention Device?

Only trained professionals can work on a backflow prevention device. Licensed plumbers with specific backflow training handle installation and repairs. At Allied Plumbing, Heating & Cooling, our team has served Springfield, Chatham, Rochester, and Pleasant Plains since 1977 with this specialized knowledge of local codes and technical requirements.

Certified testers must pass rigorous exams and use calibrated equipment to perform inspections. This ensures public health is protected. When you choose our team for Commercial Plumber in Springfield, you get qualified professionals. Learn more about the Benefits of Hiring Our Commercial Plumbers.

Common Causes of Leaks and Failures

Even the best backflow prevention device can fail. Here are common causes:

- Debris in the valves: Sediment or rust can prevent valves from sealing properly, causing leaks or failure.

- Worn seals and O-rings: These rubber components create watertight seals but degrade over time, leading to leaks.

- Improper installation: Incorrect orientation or overtightening can cause immediate or premature failure. Professional installation is essential.

- Freezing temperatures: Water expands when it freezes, which can crack the device. Outdoor installations require proper winterization.

- High water pressure: Excessive or fluctuating pressure strains internal components, causing premature wear.

- Corrosion: Over years, metal parts can weaken and leak due to exposure to water.

If you notice a leak, it’s a sign your protection system isn’t working. Our team can diagnose and fix these issues. For other plumbing concerns, see our guide on Signs of Hidden Water Leaks.

Frequently Asked Questions about Backflow Prevention

Here are answers to the most common questions we receive from customers about backflow prevention device systems.

How do I know if my property needs a backflow preventer?

Whether you need a backflow prevention device depends on your property type, water usage, and local regulations. Commercial, industrial, and large multi-residential properties almost always require one. For residential properties, common cross-connections like irrigation systems, fire sprinklers, boilers, or private wells often necessitate a device.

Local plumbing codes dictate the specific requirements. Our team knows the codes for Springfield, Chatham, Rochester, and Pleasant Plains and can assess your property to determine your exact needs to stay compliant and keep your water safe.

How often does a backflow device need to be tested?

Testable backflow prevention devices require regular inspection by a certified tester. Testing is mandatory:

- Annually: Most local water authorities require a yearly test.

- At installation: A new device must be tested to ensure it works correctly.

- After repairs: Testing is required again to verify the fix was successful.

Our certified team handles the entire process, including submitting test results to the local water authority, so you don’t have to worry about compliance.

What are the consequences of not having proper backflow prevention?

The consequences of inadequate backflow prevention are severe and can impact the entire community.

- Public Health Hazards: Contamination from sewage, chemicals, or fertilizers can enter the public drinking water, causing widespread illness like amoebic dysentery or chemical poisoning.

- Legal Liability: Property owners can be held liable for damages and illnesses caused by a backflow incident originating from their property.

- Fines and Service Disconnection: Water authorities can issue substantial fines for non-compliance and may even shut off water service to a property that poses a threat.

- Reputation Damage: For businesses, a backflow incident can cause irreparable harm to their reputation.

Proper installation and testing is a small investment compared to these catastrophic risks. It’s about being a good neighbor and protecting everyone who shares the water supply.

Conclusion: Your Partner in Protecting Our Water Supply

A backflow prevention device is a critical safeguard for our clean drinking water, protecting it from contamination caused by back-pressure or back-siphonage. As history shows, the consequences of failure can be devastating. From simple air gaps to complex Reduced Pressure Zone Assemblies, each device plays a role in this vital defense.

As a property owner, you have a responsibility to ensure your system is compliant and safe. This includes proper installation and proactive maintenance, like annual testing, which provides peace of mind and protects community health.

The regulations and technical details can be complex, but you don’t have to manage them alone. Since 1977, Allied Plumbing, Heating & Cooling has provided reliable, prompt, and professional service to the Springfield area. Our certified experts take the responsibility of protecting your water supply seriously, bringing decades of experience and our Daikin Comfort Promise to every installation, test, and repair.

Don’t leave water safety to chance. For expert service on your backflow prevention system, reach out to our plumbers in Sherman. We are your trusted partner in keeping our community’s water safe and clean.